Understanding the Cost of a PVC Roof: Key Factors to Consider

admin

2024-09-26

131

When planning to install a PVC roof, understanding the cost factors is essential for making an informed decision. The price of PVC resin tiles (commonly referred to as resin瓦) depends on several variables, including thickness, material type, project area, and transportation fees. As a professional manufacturer specializing in high-quality resin tiles, we offer competitive pricing and tailored solutions. Below, we break down the cost components to help you budget effectively.

1. Thickness of Resin Tiles

The thickness of PVC resin tiles significantly impacts both performance and cost. Standard thickness options range from **2.0mm to 3.0mm**, with thicker tiles offering enhanced durability, weather resistance, and load-bearing capacity. For instance:

2.0mm tiles**: Ideal for residential projects with moderate weather conditions.

2.5mm tiles**: Suitable for commercial buildings or regions prone to heavy rain or wind.

3.0mm tiles**: Recommended for industrial structures or extreme climates.

Thicker tiles naturally cost more per square meter due to higher material usage. However, they provide long-term savings by reducing maintenance and replacement expenses.

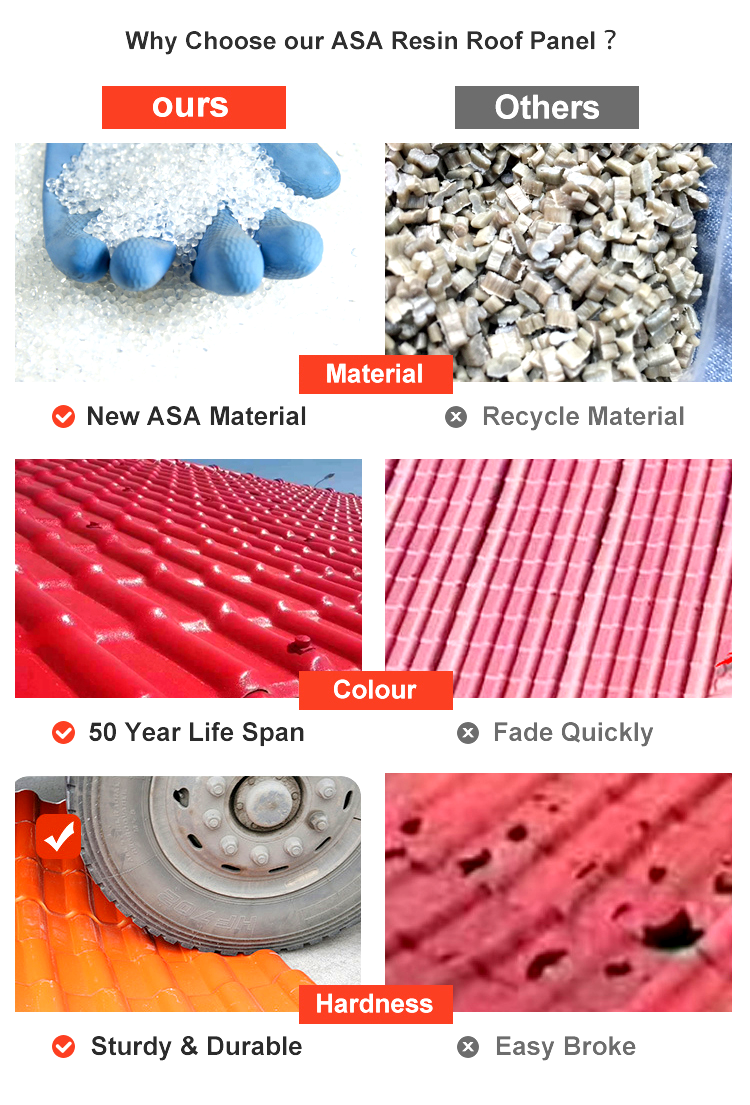

2. Material Type and Quality

PVC resin tiles come in different grades, depending on additives and coatings. Standard PVC tiles are affordable and corrosion-resistant, while premium options may include:

ASA (Acrylonitrile Styrene Acrylate) coatings**: Enhance UV resistance and color retention.

Fire-retardant additives**: Critical for buildings requiring strict fire safety compliance.

Anti-static coatings**: Useful in industrial environments.

Higher-grade materials increase upfront costs but extend the roof’s lifespan and performance. Our factory uses advanced formulations to balance quality and affordability.

3. Project Area

The total roof area directly influences the overall cost. Larger projects benefit from economies of scale, meaning the price per square meter decreases as the quantity increases. For example:

Small projects (under 100㎡)**: May incur higher per-unit costs due to setup and cutting fees.

Medium to large projects (100–500㎡ or more)**: Enjoy bulk discounts and optimized production efficiency.

We provide customized quotes based on your specific measurements to ensure cost-effectiveness.

4. Transportation Fees

Shipping costs depend on the delivery distance and order volume. Local projects typically have minimal transportation fees, while international or remote deliveries may require additional logistics planning. To minimize expenses, we optimize packaging and collaborate with reliable freight partners. Bulk orders often qualify for discounted shipping rates.

Why Choose Us?

As a professional resin tile manufacturer**, we combine cutting-edge technology with stringent quality control to deliver superior PVC roofing solutions. Our advantages include:

Cost competitiveness**: Direct factory pricing without middleman markups.

Customization**: Tiles tailored to your preferred thickness, color, and specifications.

Technical expertise**: Guidance on material selection and installation best practices.

Whether you need standard or specialty resin tiles, we ensure a balance of affordability, durability, and aesthetic appeal.